for the Mark I (1948 - 1951)

F.C.Williams and Tom Kilburn had foreseen the need for a magnetic drum backing store that would supplement the CRT store that had been the stimulus for the "baby" earlier in 1948.

They had set about in typical Manchester fashion building it from whatever was available.

The configuration of a rotating magnetic surface was quickly determined by the storage capacity and characteristics of the CRT store. It only remained to find a suitable piece of brass and build it.

I was not a witness to the process, but I believe F.C. did a search through the stores of the Physics and Electrical Engineering Depts and came up with a discarded component from a cloud chamber experiment of roughly the right dimensions.

Unfortunately I have not been able to recover a photo of the mechanism that was then constructed to spin around an induction motor coil and with a clever servo engineered by Cliff West and F.C. was synchronised with the waveforms of the CRT store. If there is one, please register it in the Manchester collection it was quite an achievement for the workshops of the University at that time.

It was at this stage that I was assigned to the task of assisting F.C. make the drum into an intermediary store for the projected prototype computer. The choice of Nickel as the recording medium and the adaptation of the Booth single wire recording head is well documented. The day when F.C having made his selection of Nickel looked out of the windows of the lab and spotted the motor cycle component electroplating shop across the road was magic. Off goes F.C. clutching the body of the drum and arranges within the week for the return of our plated surface ready to start a series of developments which did not find a better medium within the span of this recollection. How many months had been saved?

Then followed the development of the twin read/write blocks of 16 heads that were to transfer the two pages per track of data to and from the Williams Tubes. These transfers were initially performed by manual switching after interrupting the execution of a programme. However this lash up made it possible to run some larger programmes on the intermediary version of the Manchester Mk1 in the summer of 1949.

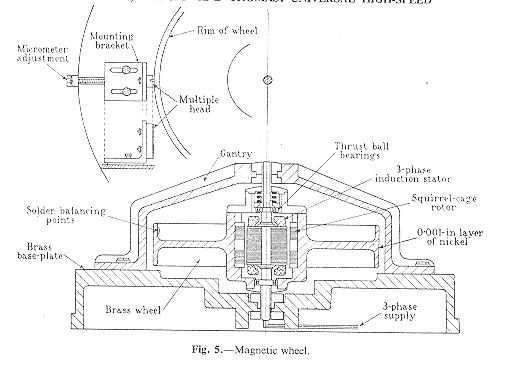

The role of this first drum built wholly in the department came to

an end with the delivery of a beautifully machined replica built by

Ferranti for the further development of the recording heads and

experimentation with the magnetic surfaces. There was also some time

for photographs and engineering drawings !!

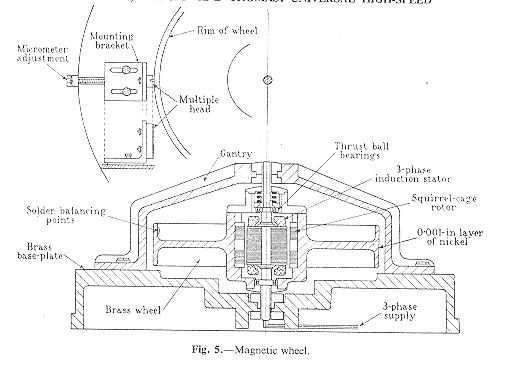

The depth of the drum of 2'' was governed by the need to achieve sufficiently small clearance between the recording heads and the recording surface over its full extent.

The storage of 64 x 40 bit words which constituted two pages (CRT tube capacity) at the packing density of our recording system determined the periphery and hence the diameter of 12"

The robust base plate and gantry to support the thrust bearings were a joy to behold. When the day came for F.C. to want to penetrate the rotor area ( for some instant improvement) we found that very wisely Ferranti had not given us the necessary tools.

The use of a screwdriver and hammer by F.C to affect his purpose

led to a rather emotional scene later between him and Brian Pollard.

Manchester screwdrivers were alive and well in those days too.

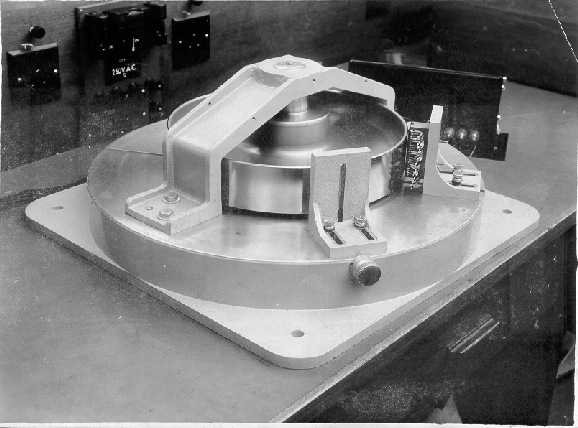

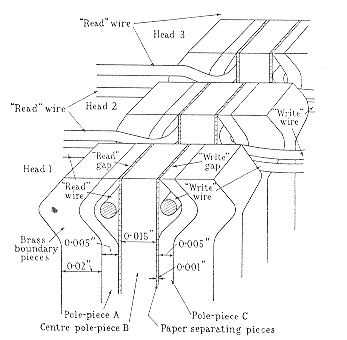

Here we have one of the experimental blocks of heads, Mr Punch was probably provided by the pipe smoking Tom.

The delicate job of threading thin wire past sharp pole-pieces was all undertaken in the department's workshops. In each bank of heads you will notice, if you count the individual heads carefully, four extra were added in each bank of twenty to allow for failures.

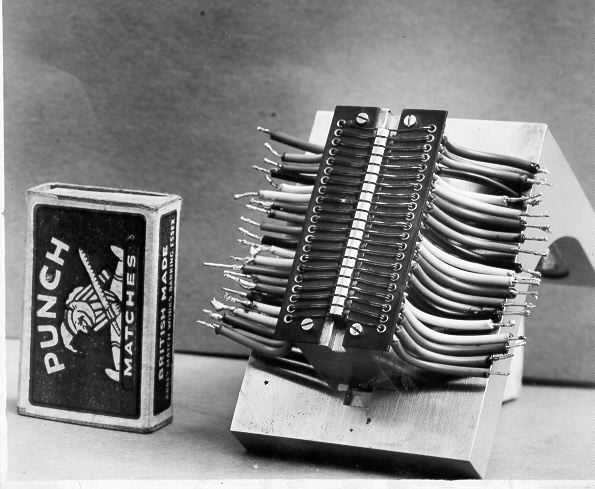

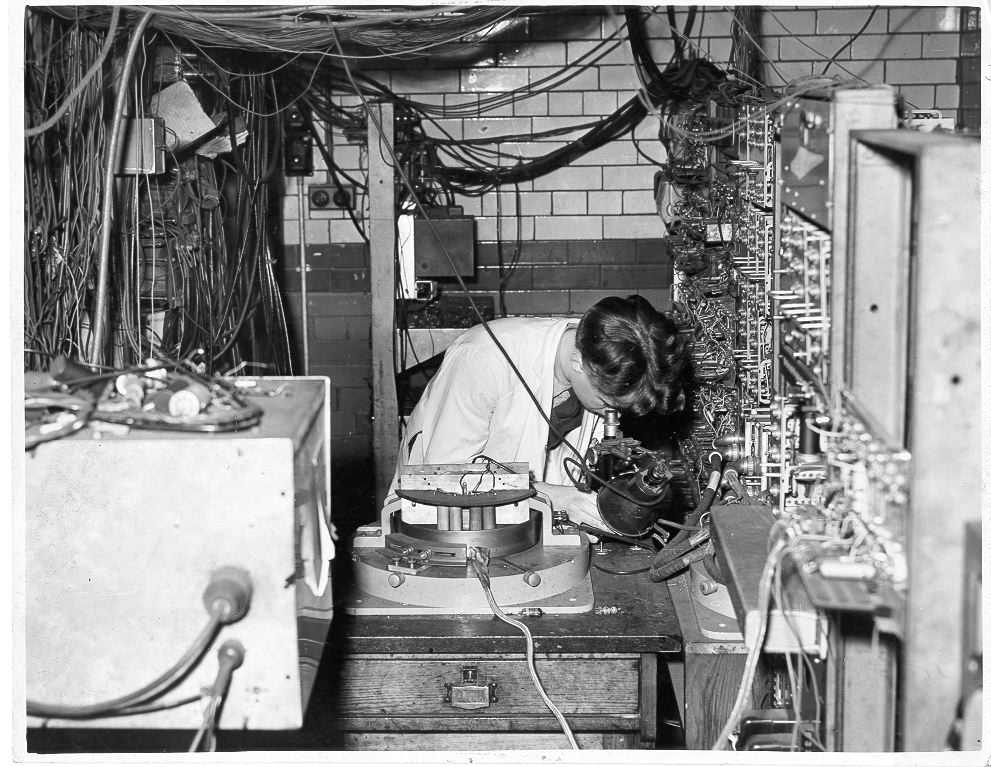

This first Ferranti engineered drum was soon surrounded by the customary maze of wires and circuit racks as this photograph of the time reveals. There was even a little room for the author!

It was through use of these components that by October of 1949 the Manchester Mark1 had access to two magnetic drums each with 32 tracks (two blocks of 16 heads per drum) providing an effective intermediate store of 128 pages, 16 times the capacity of the random access CRT store of eight pages. Dai Edwards had built the transfer circuitry to provide for programmed control of the drum transfers and we had a practical system working with two levels of storage for the programmers to spread their wings in.We could start to prepare for the next project.

The Manchester Mark 1 continued as a test bed for programmers and the Ferranti engineers until the summer of 1951 when the Ferranti Mark1 was delivered.

Ferranti engineers had substantially reengineered the magnetic store while retaining a synchronised drum principle. The drum's dimensions changed drastically with a reduced diameter of 6 inches and a length of 8 inches.

Each drum had up to 256 separate peripheral tracks accessed by up to 16 blocks of 16 heads with each track holding 64 words each of 40 digits. The total upper capacity of each drum was 655,360 digits or 82K bytes in today's jargon, 6% of a floppy disc!

In fact the images we have so far displayed in this paper would in digital format have consumed the complete storage capacity of the Ferranti Mark 1!

How times have changed.